Technical Information

NGK Fine Molds creates new products and technologies based on its core technologies of molds to achieve a carbon neutral and digital society.

High-Cycle

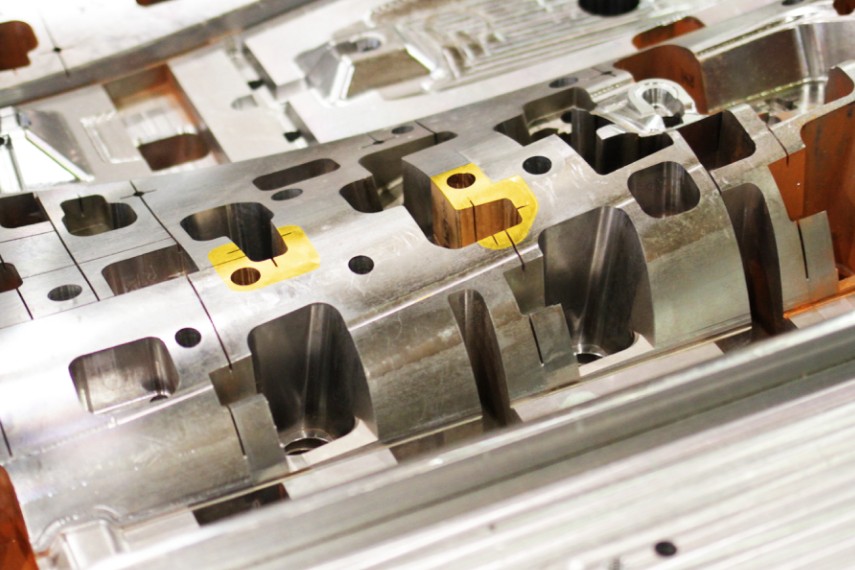

Contribution to high-cycle molding using beryllium copper

We use high-cycle technology and know-how accumulated over many years to shorten cycle time and improve quality in plastic injection molding and die-cast molding.

DG coating (Hard coating)

Hard coatings for engineering plastics with glass fibers

The thin film achieves strong adhesion and high hardness, keeps the high thermal conductivity of the base beryllium, and achieves high-cycle performance.

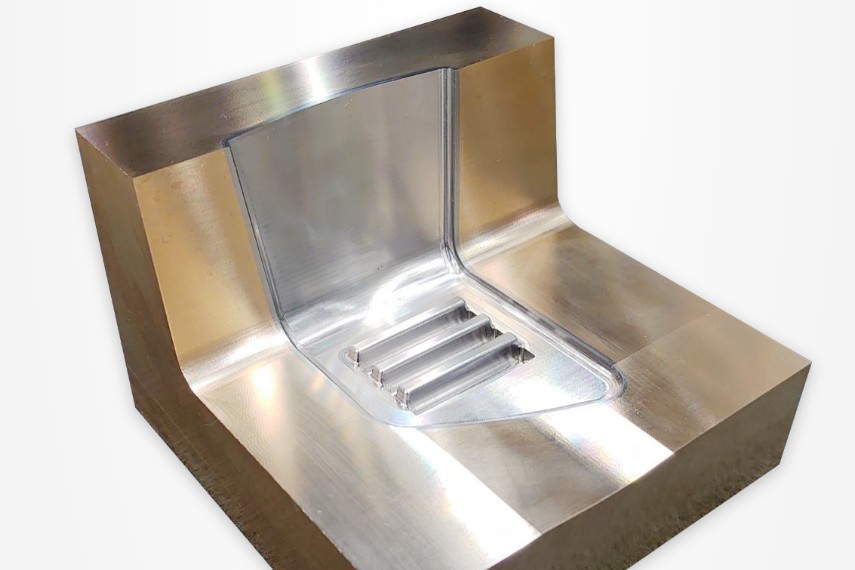

Metal additive manufacturing

Metal additive manufacturing with further improved durability

We offer high-cycle, long-life molds and parts that combine the high strength and high thermal conductivity characteristics of beryllium copper with the wear resistance of SKD61.

Facilities

Facilities list of machine type and number

We have the design, machining, inspection and measurement facilities to meet our customer's mold and part requirements.

Learn more